NCC Acoustic Louvers offer three base material options: aluminum alloy, galvanized steel, and stainless steel. Aluminum alloy is lightweight and weather-resistant; galvanized steel is economical and practical; stainless steel is suitable for highly corrosive environments. Users need to make precise selections based on the climatic conditions and durability requirements of the project location.

Surface treatment processes directly affect the service life of the product. NCC Acoustic Louvers support the following treatment methods:

Airflow rate, pressure loss, and acoustic class form the core "performance triangle". There is a trade-off between airflow rate and acoustic class: the higher the ventilation efficiency, the weaker the noise reduction performance tends to be. During selection, it is necessary to combine air velocity, noise frequency, and allowable pressure loss, and customize a balanced solution through calculation models.

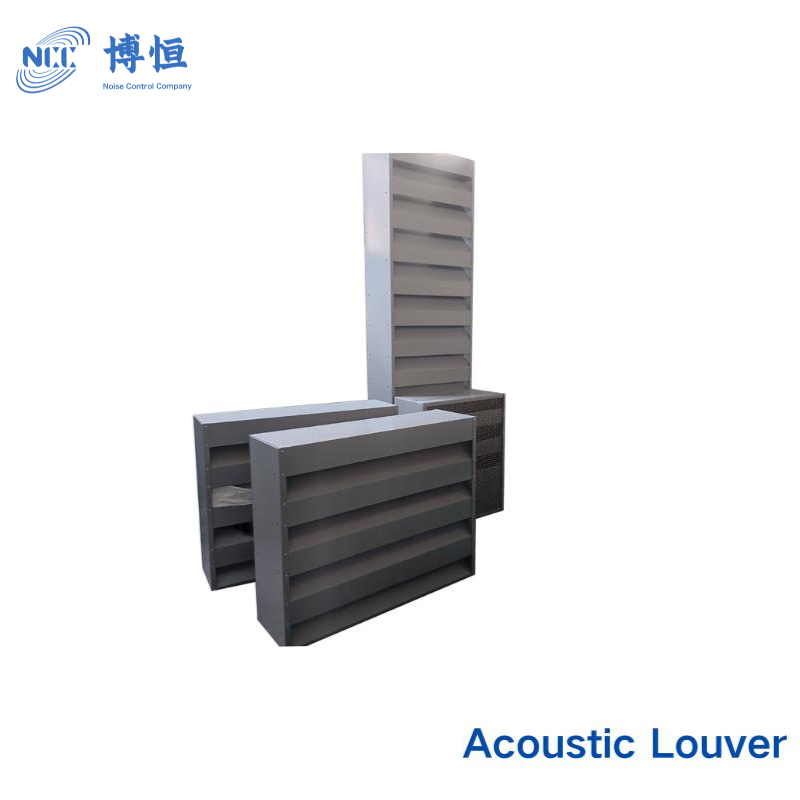

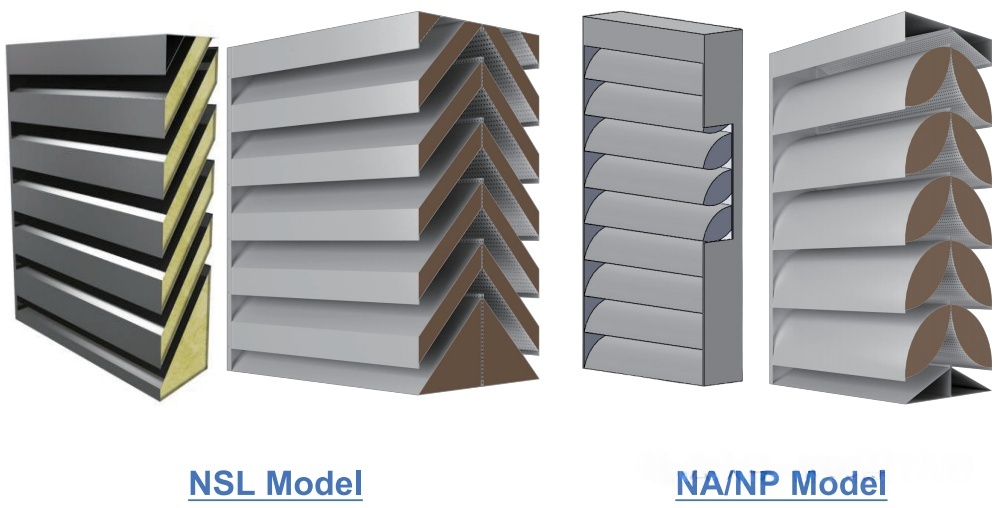

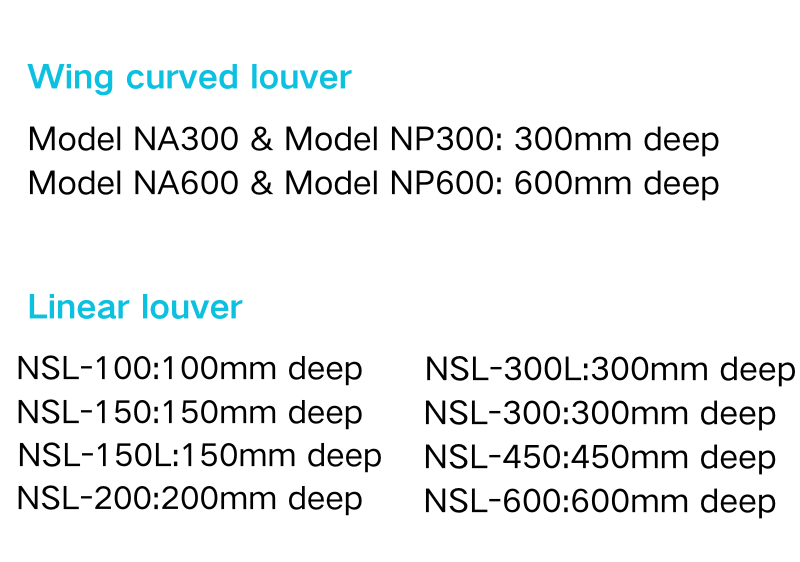

NCC Acoustic Louvers cover three main models: NSL (Linear Type) and NA & NP (Airfoil Type). They are further subdivided into multiple sub-models based on differences in louver depth, airflow rate, acoustic class, and other parameters:

Airfoil-Type Louvers: Designed based on aerodynamics, they feature lower pressure loss, making them suitable for scenarios requiring high ventilation efficiency.

Linear-Type Louvers: Offer better acoustic performance at the same depth, ideal for environments where noise reduction is a higher priority. The entire series supports non-standard customization to ensure precise alignment with building structures, noise spectra, and spatial aesthetics.

03 Derived Applications: From Louvers to Integrated Systems

Building on acoustic louver technology, NCC has further developed derivative products: "Acoustic Louver Doors", "Louver Sound Barriers", and "Energy Storage Silencers".

-Acoustic Louver Doors integrate ventilation and noise reduction functions with door bodies, are equipped with stainless steel hardware, and are suitable for places like equipment rooms and substations that require both sound insulation and access:

-Louver sound barriers are composed of louver modules and are suitable for noise reduction in cooling towers:

-Energy Storage Ventilation Acoustic Enclosures are specifically designed for energy storage cabinets. There are currently two models: QUIET-10 and QUIET-15, which effectively reduce noise by 10dB and 15dB respectively while ensuring energy efficiency and heat dissipation.

NCC Acoustic Louvers have obtained certifications from AMCA (Air Movement and Control Association) in the United States and BSRIA (Building Services Research and Information Association) in the United Kingdom. Data regarding the acoustic, rainproof, and sandproof performance of the louvers has all been tested by internationally authoritative laboratories. Currently, the brand continues to develop new models to meet the diverse needs of global customers for energy efficiency, acoustics, and aesthetics.

The essence of NCC Acoustic Louvers lies in finding the optimal balance between "acoustics" and "ventilation". Whether it is the noise reduction enhancement of the Linear-Type or the efficiency priority of the Airfoil-Type, their core lies in customized design based on scientific parameters. In today’s world where green environments are increasingly valued, choosing a rigorously verified acoustic louver has become an inevitable step to improve building quality.

administrators

No comment on this content